| Fuenlabrada Hospital | |

| Madrid, Spain | |

| Typologie | Hospitals |

| Date | Janvier, 2004 |

| Mission | Detailed design and construction monitoring |

| Architecte | Andres Perea Ortega & Luis Gonzalez Sterling |

| Maîtrise d'ouvrage | Comunidad de Madrid |

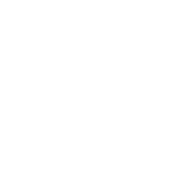

The Fuenlabrada Hospital has a surface area of 159.50 x 12300m on plan. From the beginning of the project, a pre-cast structure with rigid nodes and no expansion joints was considered.

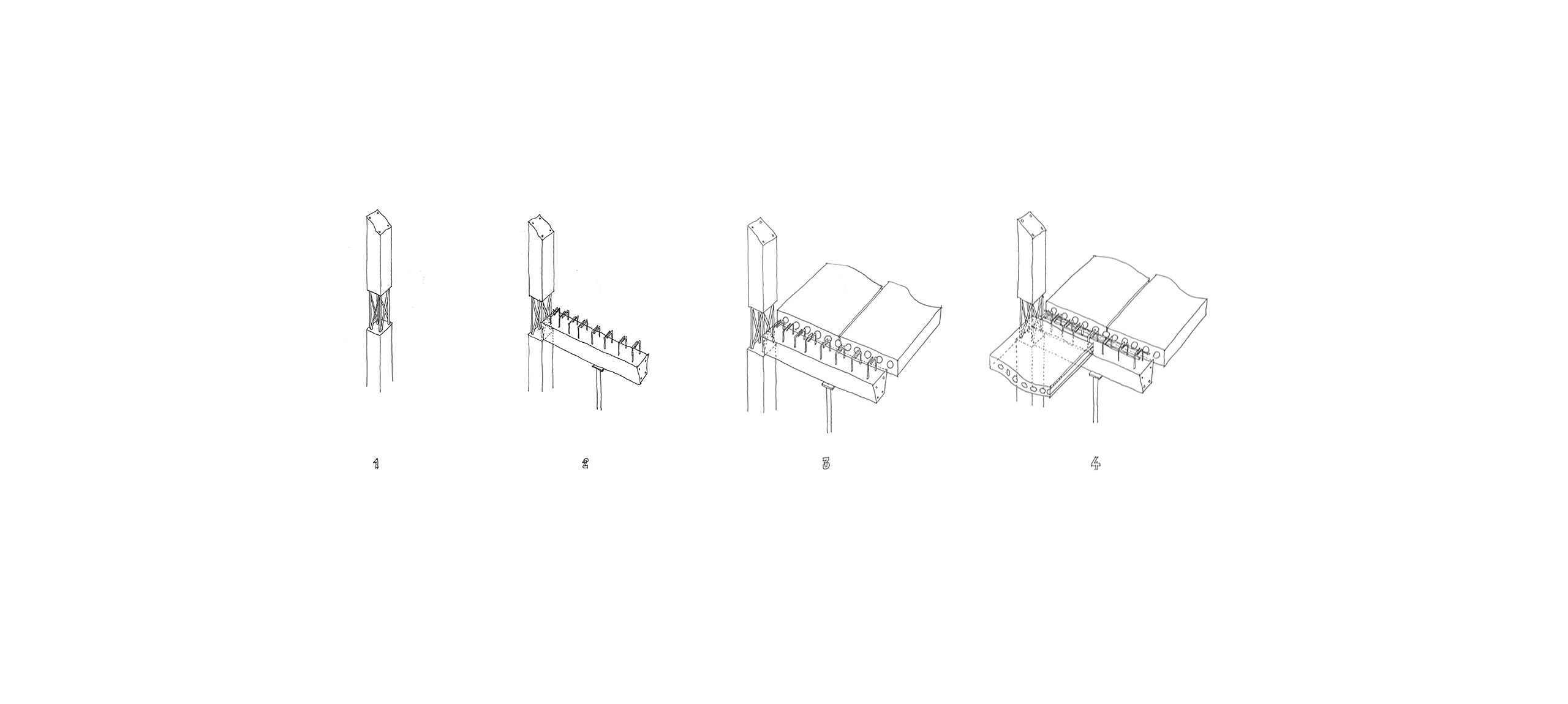

The basic structure consists of frames with spans of 5.0m to 7.50m in one direction, and pre-cast slabs in the other. The frames are composed of 0.3 x 0.3m pre-cast columns which are installed in one piece and go throughout the six floors of the building. Afterwards, the pre-cast beams are propped up and the pre-cast hollow slabs placed between them. The concrete is then cast, simultaneously, over the upper layer of the slabs, the upper part of the beam and the column-beam joints,

offering a completely monolithic result. Designed without joints, the structure is anchored to the vertical circulation cores in order to prevent the effects caused by horizontal loads and weather-conditioned shrinkage. Although, initially, these cores were meant to be pre-cast elements, they were finally built in-situ. The building also contains several pre-cast footbridges.

This construction project is a fine example of how to achieve a highly modular building using non-standard pre-cast elements and at the same time, optimizing the construction period whilst taking advantage of the highest quality, industrialized construction may offer.

The basic structure consists of frames with spans of 5.0m to 7.50m in one direction, and pre-cast slabs in the other. The frames are composed of 0.3 x 0.3m pre-cast columns which are installed in one piece and go throughout the six floors of the building. Afterwards, the pre-cast beams are propped up and the pre-cast hollow slabs placed between them. The concrete is then cast, simultaneously, over the upper layer of the slabs, the upper part of the beam and the column-beam joints,

offering a completely monolithic result. Designed without joints, the structure is anchored to the vertical circulation cores in order to prevent the effects caused by horizontal loads and weather-conditioned shrinkage. Although, initially, these cores were meant to be pre-cast elements, they were finally built in-situ. The building also contains several pre-cast footbridges.

This construction project is a fine example of how to achieve a highly modular building using non-standard pre-cast elements and at the same time, optimizing the construction period whilst taking advantage of the highest quality, industrialized construction may offer.