| High speed railway viaduct over EX-A1 and EX-108 highways | |

| Extremadura, Spain | |

| Typologie | Railway Bridges |

| Date | Décembre, 2025 |

| Mission | Detailed design |

| Client | FERROVIAL |

| Design | Fhecor |

| Maîtrise d'ouvrage | ADIF Alta Velocidad |

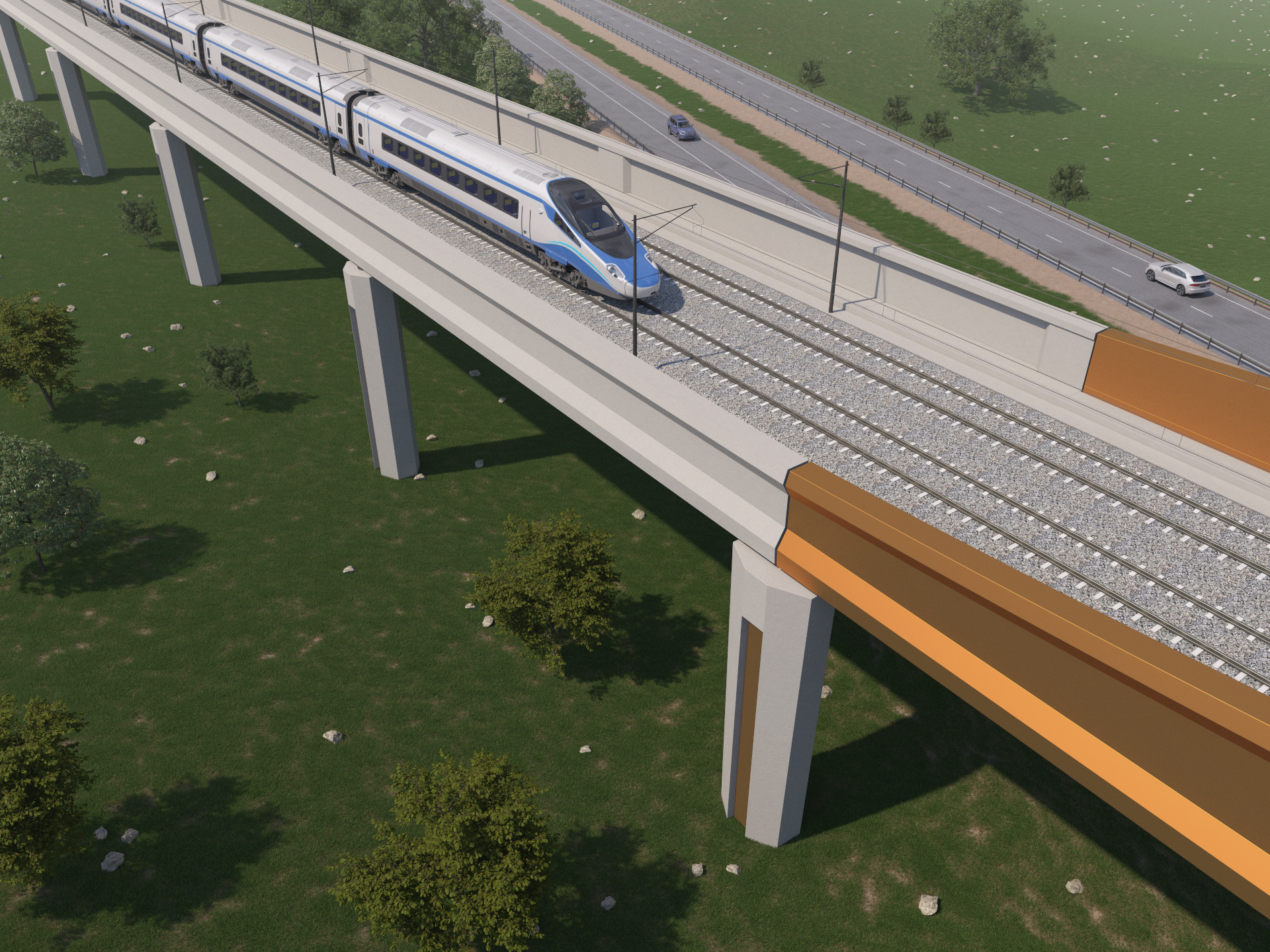

The new viaduct will allow the High-Speed Rail line to cross over the EX-108 road and the EX-A1 highway near the town of Malpartida de Plasencia. The crossings over these two roads involve a significant skew—approximately 19° and 17° at the intersections with the EX-108 and EX-A1, respectively. This pronounced skew heavily influences the span layout of the viaduct.

The design speed for train circulation is 330 km/h.

The Modified Project for the viaduct proposes a structure with a total length of 613 meters, divided into five sections: two made of steel trusses for the crossings over the EX-108 and EX-A1 roads, and three made of concrete to complete the total length of the viaduct. The characteristics of each section are as follows:

- Section 1 (E1 to P2): Concrete. Spans: 31.50 + 31.50 m

- Section 2 (P2 to P4): Steel. Spans: 45.00 + 45.00 m

- Section 3 (P4 to P8): Concrete. Spans: 31.50 + 36.00 + 36.00 + 31.50 m

- Section 4 (P8 to P11): Steel. Spans: 57.70 + 67.00 + 57.70 m

- Section 5 (P11 to E2): Concrete. Spans: 31.50 + 36.00 + 36.00 + 31.50 m

The viaduct features two clearly distinct typologies. On one hand, two sections employ steel trusses for the crossings over the existing roads, continuing the concept developed in the original project. On the other hand, three concrete sections are proposed to complete the total length of the viaduct.

The design speed for train circulation is 330 km/h.

The Modified Project for the viaduct proposes a structure with a total length of 613 meters, divided into five sections: two made of steel trusses for the crossings over the EX-108 and EX-A1 roads, and three made of concrete to complete the total length of the viaduct. The characteristics of each section are as follows:

- Section 1 (E1 to P2): Concrete. Spans: 31.50 + 31.50 m

- Section 2 (P2 to P4): Steel. Spans: 45.00 + 45.00 m

- Section 3 (P4 to P8): Concrete. Spans: 31.50 + 36.00 + 36.00 + 31.50 m

- Section 4 (P8 to P11): Steel. Spans: 57.70 + 67.00 + 57.70 m

- Section 5 (P11 to E2): Concrete. Spans: 31.50 + 36.00 + 36.00 + 31.50 m

The viaduct features two clearly distinct typologies. On one hand, two sections employ steel trusses for the crossings over the existing roads, continuing the concept developed in the original project. On the other hand, three concrete sections are proposed to complete the total length of the viaduct.