| New Champlain Bridge over St Lawrence river | |

| Montreal, Canadá | |

| Structural typology | Cable Stay Bridges |

| Date | January, 2019 |

| Scope | Construction support |

| Owner | Canadian Ministry of Infrastructure |

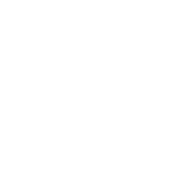

The existing Champlain Bridge is located in one of the busiest road transportation corridors, having more than 50 million cars, buses and trucks crossing it per year. Now, the new 3.4 km Champlain Bridge has been constructed and it has been a big engineering challenge.

The new bridge spans Saint Lawrence River. The structure was planned as a group of three: the East Approach Viaduct, the Main Bridge and the West Approach Viaduct.

The structure is formed by three composite decks. Light-rail from Montreal metro network will go over the central one. The other two will be used for road traffic and also, cyclists and pedestrians will be able to cross the bridge over one of them.

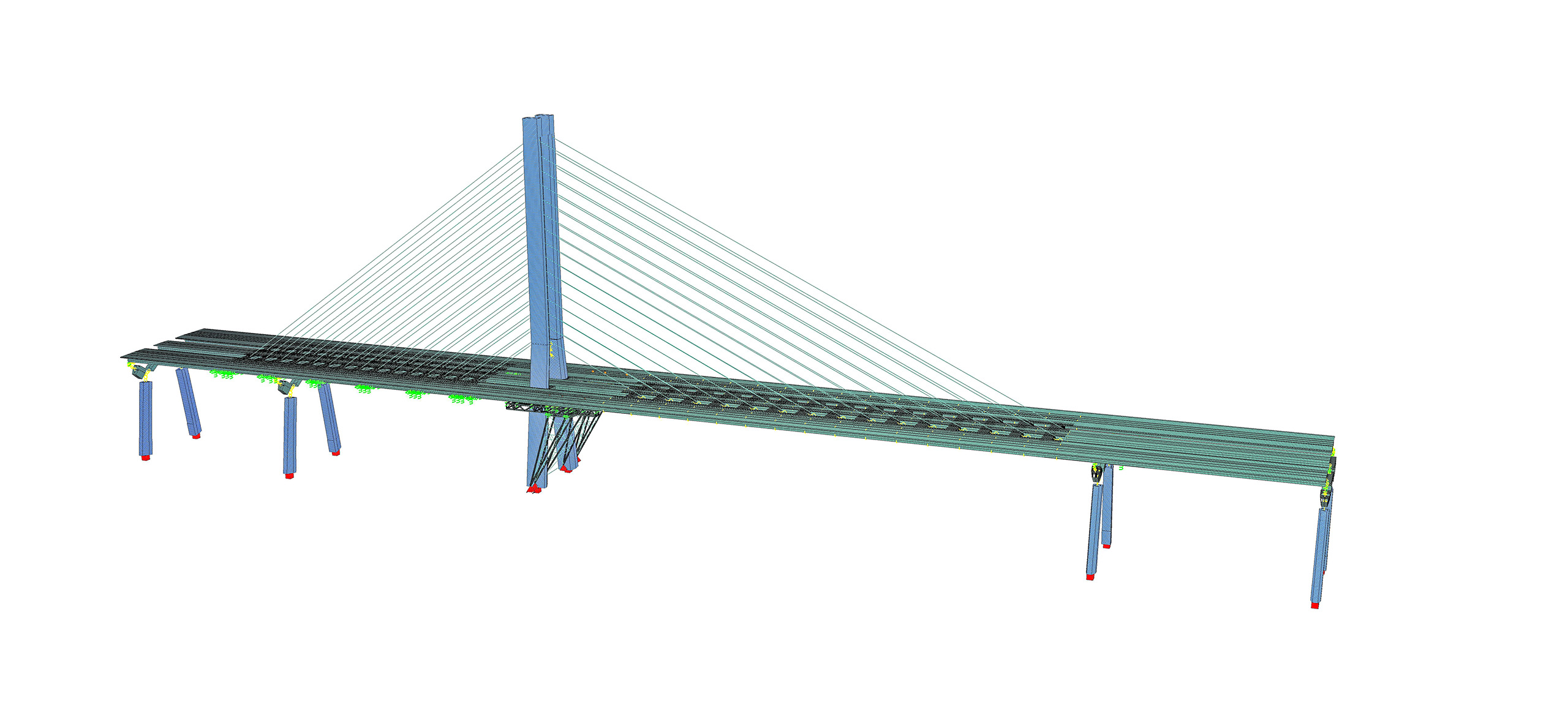

The Main Bridge is a one pylon cable-stayed bridge, spanning 240 m at 38 m over the water level. The pylon is 160 m high, and its configuration shows two vertical towers. Cables display a harp shape and are anchored to the towers as well as to the deck transversal cross-beams. These beams are located every 8.4 m in the back span and every 12.6 in the main span. They connect the three composite decks, so the total width of the bridge is 60 m.

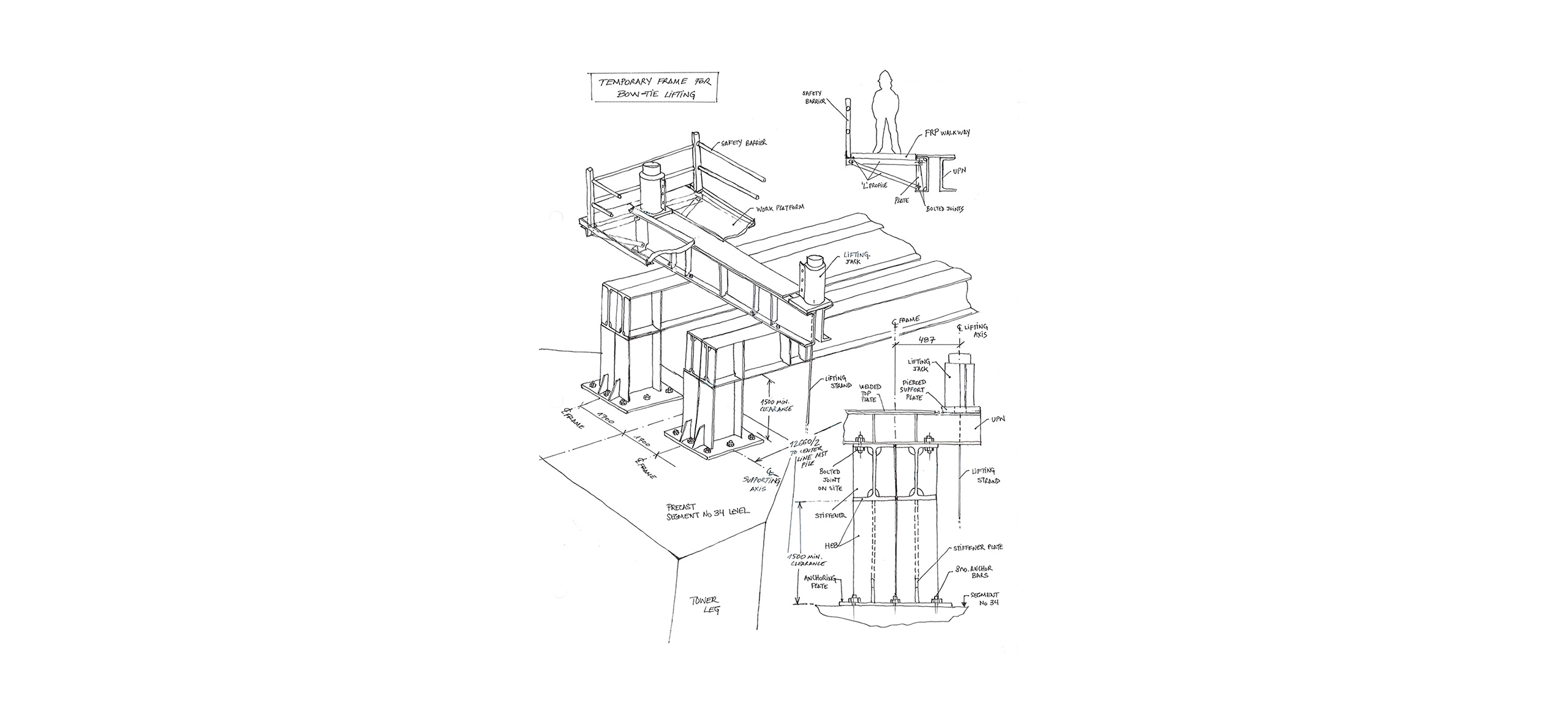

FHECOR has been part of the Construction Engineering Team for the cable-stayed bridge. We´ve been designing construction processes, as well as the many auxiliary elements needed for building this big structure. We want to highlight some of our works in the construction of the New Champlain Bridge:

The new bridge spans Saint Lawrence River. The structure was planned as a group of three: the East Approach Viaduct, the Main Bridge and the West Approach Viaduct.

The structure is formed by three composite decks. Light-rail from Montreal metro network will go over the central one. The other two will be used for road traffic and also, cyclists and pedestrians will be able to cross the bridge over one of them.

The Main Bridge is a one pylon cable-stayed bridge, spanning 240 m at 38 m over the water level. The pylon is 160 m high, and its configuration shows two vertical towers. Cables display a harp shape and are anchored to the towers as well as to the deck transversal cross-beams. These beams are located every 8.4 m in the back span and every 12.6 in the main span. They connect the three composite decks, so the total width of the bridge is 60 m.

FHECOR has been part of the Construction Engineering Team for the cable-stayed bridge. We´ve been designing construction processes, as well as the many auxiliary elements needed for building this big structure. We want to highlight some of our works in the construction of the New Champlain Bridge: