| Stockolm Tramway | |

| Stockolm, Sweden | |

| Structural typology | Railway Bridges |

| Date | September, 2019 |

| Scope | Tender design |

| Cliente | OHL |

| Design | Fhecor |

| Collaboration | ATESVI |

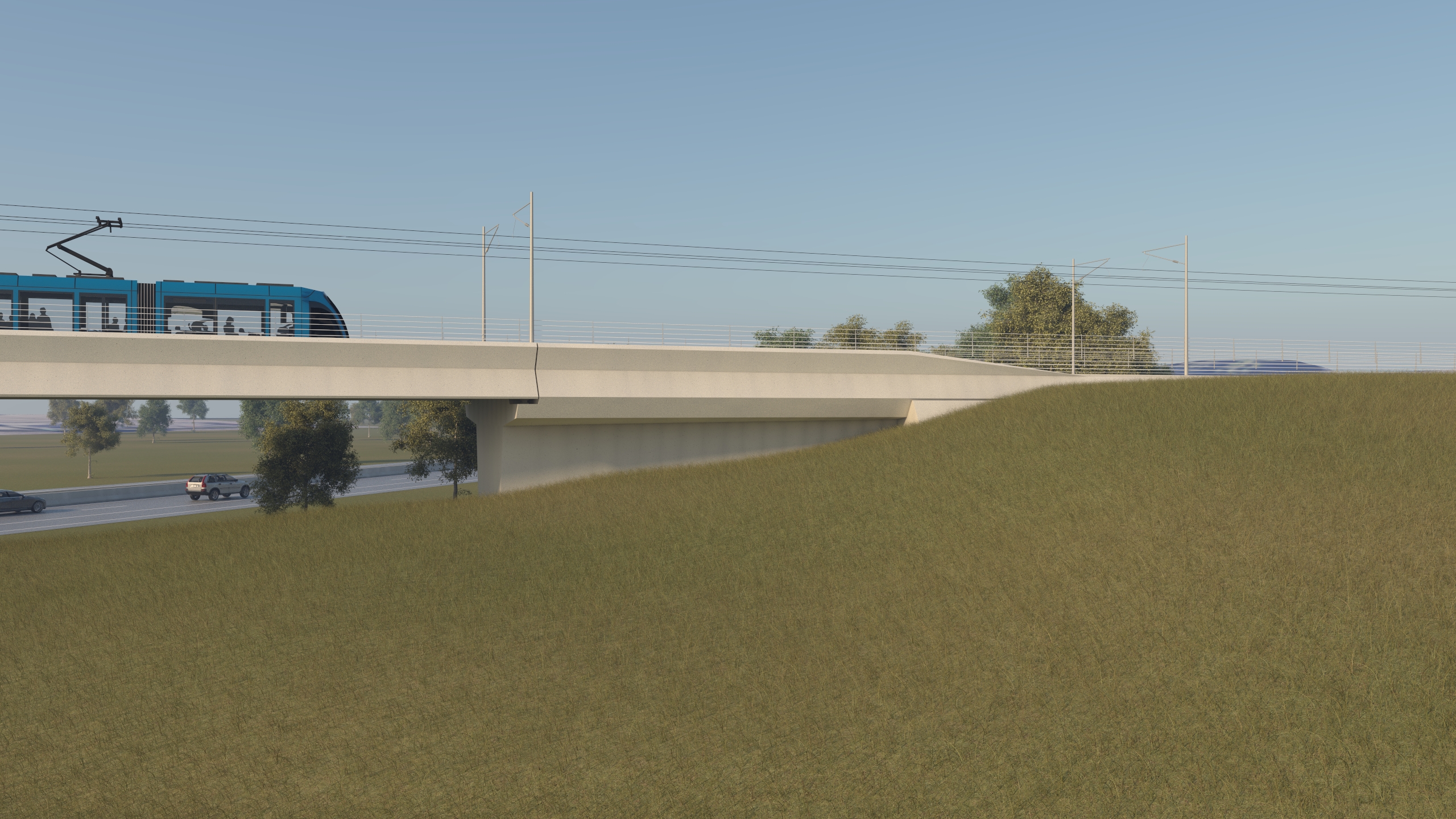

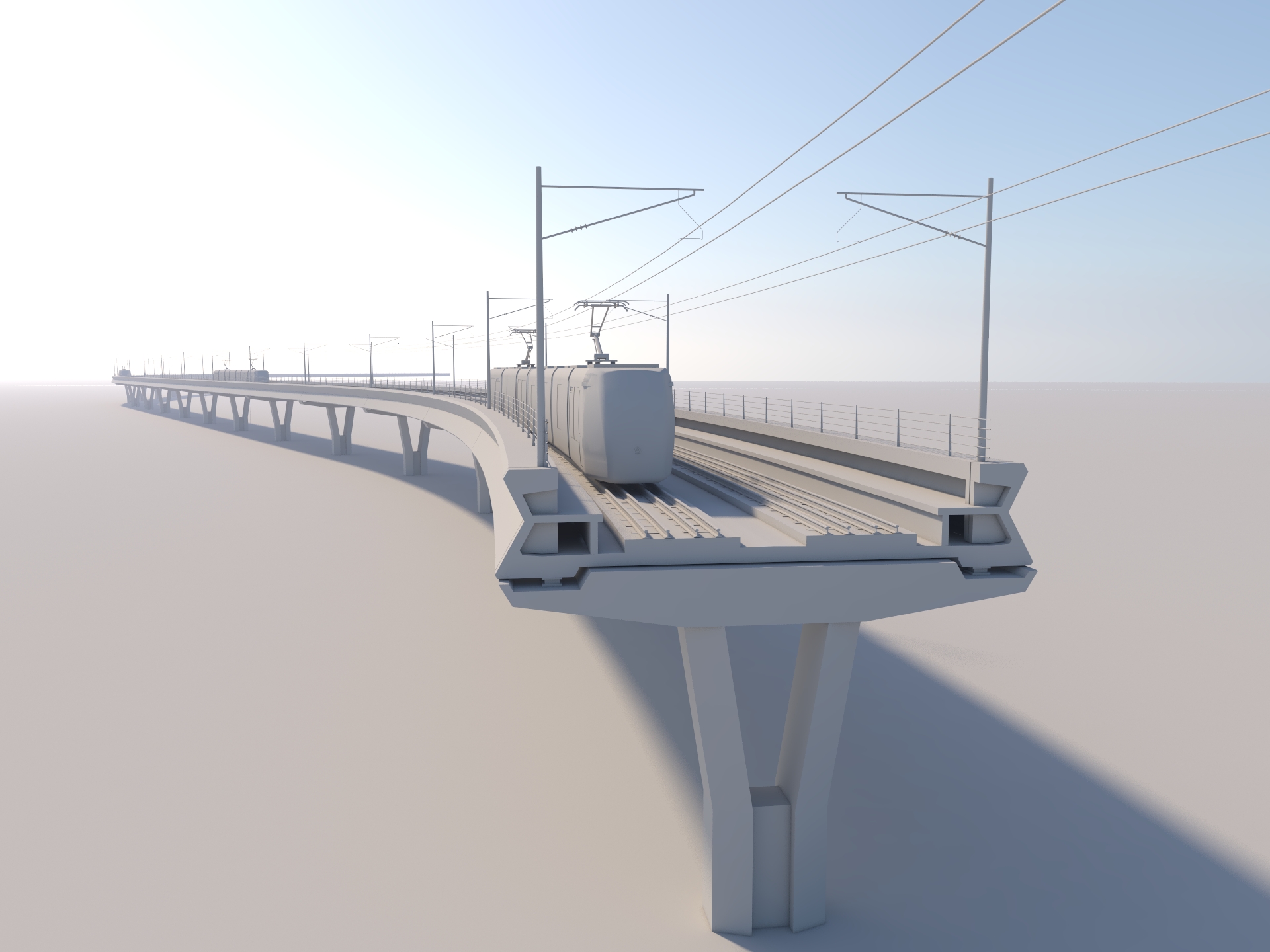

This alternative consists of two lateral beams and central slabs. The total width of the section is 11.25 m. The beams have lengths ranging from 25 m to 35 m. The slabs will span the full width between the beams and will have dimensions of 9.30 x 3.00 m. The edge slabs will have different widths to match the exact length of the deck.

The beams will be post-tensioned, with the prestressing applied in two stages: the first just before removing the mold, and the second just before transportation to the site. This approach aims to better control the camber. The slabs will be reinforced concrete.

Erection begins with the two beams of each span. Temporary supports, such as sand jacks, will be used for proper bearing, and a temporary transverse bracing will be placed between the beams. The slabs are then installed. Finally, the longitudinal and transverse joints are concreted, forming a monolithic section. All precast elements will be installed using cranes.

The substructure consists of pile caps on precast piles, piers, and crossbeams. The piers have a solid lower part of variable height, from which two branches rise with a constant height of 4 m. The piers are topped with a crossbeam, which is precast at the base of the pier and then lifted and connected to the pier shaft.

The beams will be post-tensioned, with the prestressing applied in two stages: the first just before removing the mold, and the second just before transportation to the site. This approach aims to better control the camber. The slabs will be reinforced concrete.

Erection begins with the two beams of each span. Temporary supports, such as sand jacks, will be used for proper bearing, and a temporary transverse bracing will be placed between the beams. The slabs are then installed. Finally, the longitudinal and transverse joints are concreted, forming a monolithic section. All precast elements will be installed using cranes.

The substructure consists of pile caps on precast piles, piers, and crossbeams. The piers have a solid lower part of variable height, from which two branches rise with a constant height of 4 m. The piers are topped with a crossbeam, which is precast at the base of the pier and then lifted and connected to the pier shaft.